Share

Pin

Tweet

Send

Share

Send

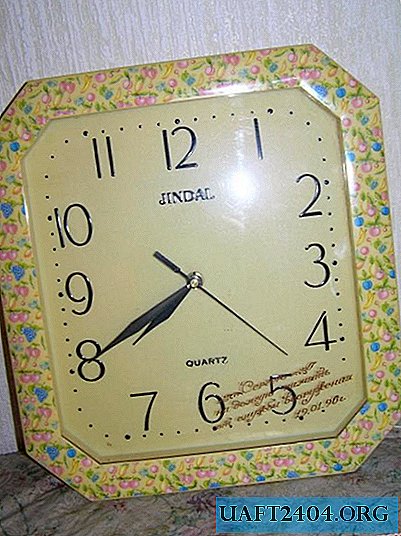

To work with the clock, we will analyze them. The dial, glass (and not plastic, as in modern watches) and the frame.

I didn’t even try to remove the clockwork, because upon careful examination, I did not find any fasteners. The decor of the dial will be accompanied by a careful rotation of the minute hand, this will complicate the work a little.

So, let's start with the framework. I decided to cover it with fabric, I just had it in stock, suitable in color. This is a fairly dense cotton fabric with elastane. When cutting, it cuts quite a bit. We attach the frame to the fabric and draw a circle for cutting, indenting along the edges for bends.

Cut out our pattern. Glue a double-sided tape on the outside of the frame to secure the fabric before tightening begins.

Having made small cuts in the corners and glued the double-sided tape inside the frame, we tighten it by carefully wrapping the edges of the fabric and gluing it to the tape. I did not choose Scotch tape by accident; the fabric adheres well to it. In this case, the glue would be impregnated through the fabric and complicate the process.

Having finished tightening the frame, I tried it on my watch. It turned out great.

And one could stop there. But the factory decor of the dial tells us that this is not a completely man-made product, it looks pretty boring. In addition, relatives really wanted a wall clock with Roman numerals. So let's get down to the dial. The dial is molded from plastic, the numbers and letters on it are part of an integral design. So I decided to putty the surface of the dial, aligning everything to zero. The height of the foot on which the arrows rotate allows us to apply 2-3 mm of putty.

Gently rotating the hands, I walked across the entire surface of the dial.

On the can with the putty it says that it dries from 3 to 24 hours, I decided to wait the maximum for reliability. A day later, I found microcracks on the surface and once again went through putty, already only rubbing these same cracks, with a layer of less than 1 mm. The second layer of cox hours 5-6.

After complete drying, with a small spatula, I slightly wiped the surface, knocking down irregularities, and wiped it with a damp sponge, removing small particles. Primed in two layers with white acrylic paint without water, with an intermediate drying of each layer. And in conclusion - the surface of the dial has been tinted with the color of acrylic paint I want without water, with random strokes. The result is such an interesting texture.

I found Roman numerals on the Internet and, in addition to them, the Eiffel Tower, which fits the style of the kitchen. I printed the image, and, placing the sheet in a plastic file, circled the picture with black stained-glass paint from the Stained-glass window children's set. Such paint when dried turns into a sticky sticker.

A day later, the numbers dried in parallel with the dial, I transferred these stickers to the dial. Gathered a watch and ...

... I hope the relatives will be happy.

Share

Pin

Tweet

Send

Share

Send