If you have an old diamond blade, do not just throw it in scrap metal. From it you can make a universal cutting blade for a gas trimmer.

This homemade disk has a lot of advantages. Firstly, it cuts dry fine grass well enough that the line does not take. Secondly, it copes with very hard grass very well.

And one of the most significant advantages of such a disk is that it cuts bushes and trees well, whose trunks and branches do not exceed 12 cm in diameter. A 180 mm disk cuts up to 60 mm at a time.

The whole secret of high performance homemade disk is in the shape and number of cutting teeth. Largely due to the special shape of the tooth, the disc does not burrow into the wood, and also does not lose momentum even on a weak trimmer.

The main stages of work

Please note: if you will use a diamond disc for a grinder, then first of all you need to drill a hole in it. The fact is that for grinder disks, the hole diameter is 20-22 mm, and for most trimmers - 25.4 mm.

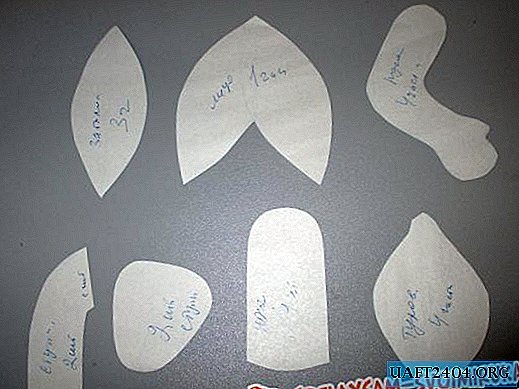

After adjusting the mounting hole to fit, attach a paper stencil to the disc. The stencil itself can be downloaded from the link.

To exclude damping slots and holes in the disk, which serve to cool and remove dust, it is necessary to reduce the initial diameter of the disk to 180 mm. Next, we cut the paper stencil clearly along the contour.

The center hole is not cut. We clean the surface of the disk from rust and dirt, apply stationery glue to it, align the stencil exactly with the landing hole and press it.

Disc manufacturing process

At the next stage, we cut off the diamond disc with a grinder according to the glued stencil. Then we clean the metal remains with a cleanup disk, reaching the edge of the stencil.

Along the way, the master cuts through the damping slots in the disk. We process the edges with a petal circle and then remove the stencil.

After that, it will be necessary to part the teeth. You can do this with ordinary pliers. However, to make the angle the same, the author uses a special wiring. Odd teeth need to be bent to the left, even - to the right.

Next, the cutting teeth must be sharpened. The optimum angle of sharpening is 15-18 degrees relative to the center. If the metal is soft, then the tips of the teeth must be hardened. To do this, simply heat them with a gas burner red-hot and dip into engine oil.

Details on how to make a universal disk for a trimmer from a diamond disk with your own hands can be found in the video on our website.