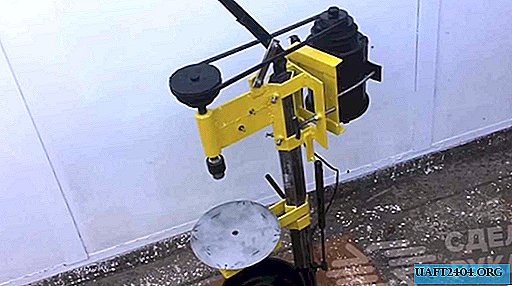

If "on duty" you often have to drill parts and workpieces made of metal or wood, and while drilling it is important to maintain an angle of 90 degrees, then you can not do without a drilling machine.

The easiest option is to buy a ready-made drilling machine (factory-made). However, you can go the other way - to make it yourself. In this case, the drive for the machine is not a drill, but an electric motor.

First of all, it will be necessary to cut a piece of pipe and two pieces of a building corner. Workpieces must be cleaned from rust with a grinder.

The corners themselves will need to be welded to the round pipe, as this is shown in the photo below. Welds must also be cleaned. To fix the workpieces, you can use parallel clamps. How to make them, read here.

The main stages of work

At the next stage, this pipe is welded to the base. Moreover, it is necessary to weld it strictly vertically, at right angles to the base. It should be massive enough.

Further, from two pieces of the corner and the plates, the author welds the carriage, which will move up and down along the stand of the drilling machine.

A square frame of pieces of a metal strip, to which the electric motor will be attached, needs to be welded to the carriage.

After that, cut a piece of round pipe and do a longitudinal cut in it. We insert a stud with a thread on the end into the pipe. We put two bearings on the stud. We wind the drill chuck on the thread. You need to weld a plate to the pipe itself. Then we weld the plate to the carriage.

Drilling Machine Assembly

We install the carriage on a rack. A plate with an eye will need to be welded to the upper end of the pipe, after which we fasten the handle to lower and raise the drill chuck.

Next, you need a circular saw blade. Four strips must be welded to it (in the form of a square frame). The teeth on the saw blade must be cut off with a grinder.

We make another carriage, and weld a frame with a disk to it. The result is a work table for parts and blanks.

Then it remains only to make two pulleys for the belt drive, and you can proceed with the assembly of the entire structure.

Details on how to make a drilling machine from an electric motor with your own hands can be found in the video on our website.