The jigsaw is very helpful when working with wooden and metal blanks (especially when you need to make curly cuts). Therefore, it is not surprising that this tool is available in almost every home workshop.

However, you can expand its functionality - for example, you can use it as a drive for a makeshift jigsaw machine. If you work with wood, then a jigsaw machine will help facilitate the processing of workpieces.

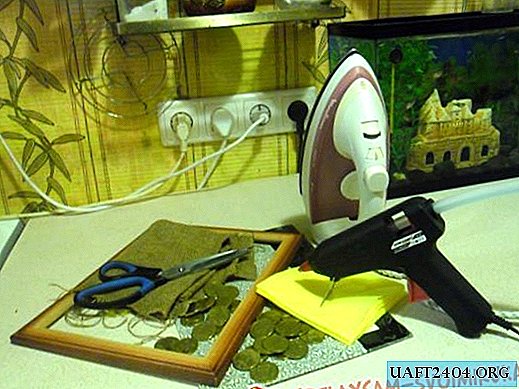

For the manufacture of a work table, a sheet of metal of round or rectangular shape, as well as trimming of the profile pipe, is required. In total, three pieces of the profile are required, and the edges must be cut off at a slight angle.

The main stages of work

In a metal circle, it is necessary to drill a hole for a jigsaw file, as well as mounting holes. Then three legs from the profile pipe are welded to the table, after which the electric jigsaw is attached.

If there were no suitable screws for fastening the jigsaw at hand, and the studs protrude from the opposite side of the metal circle, then you just need to cut them off with a grinder.

With the help of a simple home-made jigsaw machine, it is very convenient to cut various curly parts from wooden blanks. Moreover, he does not take up much space in the workshop.

For details on how to make a simple jigsaw machine with your own hands, we recommend that you look in the video on our website.