Homemade table clamp from a broken G-shaped clamp is useful in the garage and home workshop. It can be used for reliable and convenient fixing of various workpieces and parts during welding and assembly work.

As a basis for this homemade product, a part of the clamp with a screw will be required. Two metal corners will also be needed.

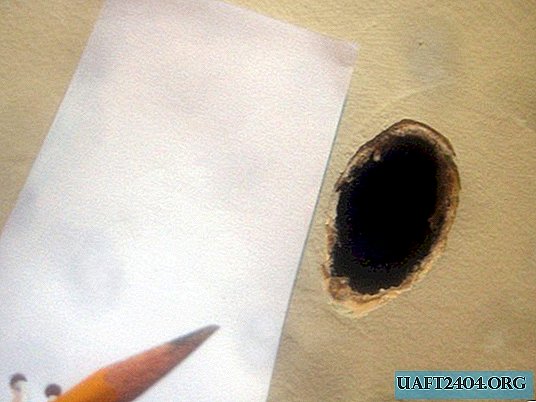

The first step is to align the end face of the clamp frame where it broke. And for this, the master uses a grinder - fixes the clamp in a bench vise, and aligns the end with a grinding disc.

The main stages of work

At the next stage, 2 holes will need to be drilled in the metal corners (in each shelf). The master does this on a drilling machine, but you can use an electric drill for this.

Also, a couple of holes will need to be drilled in the frame of the clamp itself so that the corners can be attached. And then the metal corners are screwed to the G-shaped clamp with bolts and nuts.

At the last stage of work, it remains only to screw the clamp to the surface of the table. And for this, the master uses ordinary screws. The device is ready - and you can begin to work.

Details on how to make a simple table clamp from an old broken clamp can be found in the video on the website.