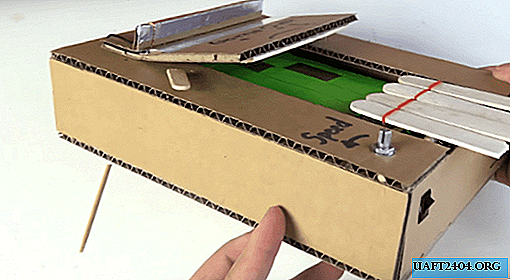

The hood in the garage or home workshop can be made from ordinary sewer pipes made of plastic, as well as the engine from a vacuum cleaner. In this case, the author uses a compact 12V motor, which was removed from a car vacuum cleaner.

Thus, you can power a homemade hood from a conventional charger. Moreover, despite its small size, the 12-volt engine copes well with the removal of smoke and dust from the room (at medium speeds).

Please note that it is advisable to immediately install a filter in front of the engine of the car vacuum cleaner, otherwise it will quickly cover. Now let's move on to the main stages of the work to be completed.

The process of installing a hood in a workshop or garage

First of all, with the help of a crown on concrete, the author makes a hole in the wall. Since the wall itself is folded into a shelf, it did not take much time. The diameter of the crown should be slightly larger than the diameter of the sewer plastic pipe.

In order to insert a wire, the author drills a hole in the pipe, and then connects the wires and isolates the twist using heat shrink. You can also use ordinary electrical tape, but the shrink tube is more practical.

Since the diameter of the engine turned out to be slightly smaller than the inner diameter of the pipe, I had to wind a little electrical tape around it. Then the author installs the motor in the pipe. After this, it is necessary to install pipe clamps on the ceiling.

The author decided to close up the small gaps around the pipe with ordinary silicone. But for this, mounting foam is better. For details on how to make an extract in the garage from sewer pipes and the engine from a vacuum cleaner, see the video on the website.