For faster dismantling of radio components from circuit boards, you can make a solder bath from an old Soviet iron. With this simple device, you don’t have to sweat with a soldering iron in your hand, soldering each leg of the part separately.

To make a solder bath, it is advisable to use an iron with a working regulator. To melt the tin, a temperature of 230-240 ° C will be sufficient. If necessary, to accelerate heating, you can trim the forefoot and a little on the sides.

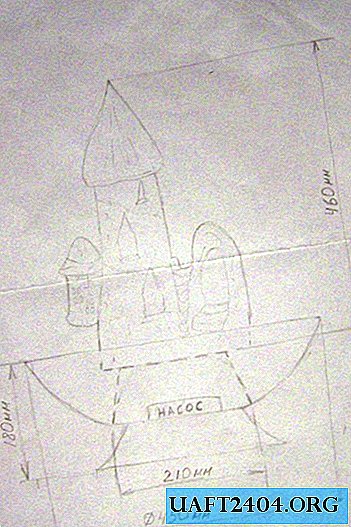

First of all, it is necessary to disassemble the iron (to separate the body from the sole), make markings on the sole and cut off all the excess. The result should be a sole of a rectangular shape. Along the perimeter, it will be necessary to fix segments of the aluminum corner with side dimensions of 15x20 mm.

The main stages of work

To make a bath for melting the solder, cut the corner in several places (cut small wedges of a triangular shape), and then bend into a box in the shape of the sole of the iron. In the sole and box itself, we drill holes and cut the threads. We fasten the box to the sole with screws.

Next, we attach the sole to the wooden base (plywood, OSB, chipboard) with three long bolts. To prevent wood burning, under the sole on the base, it is necessary to fix a sheet of thin metal (for example, galvanizing).

From the piece of metal profile, which is used to fasten drywall sheets, it will be necessary to build a protection so as not to accidentally creep into electrical wires. The device is fully assembled and ready to go.

For details on how to make a solder bath from an old iron, see the video on the site.