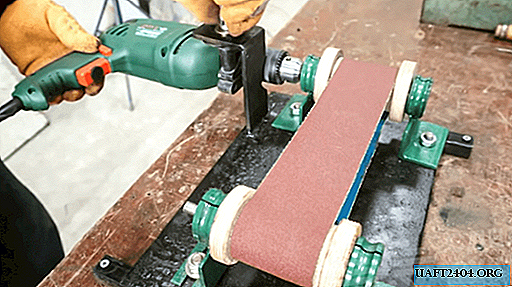

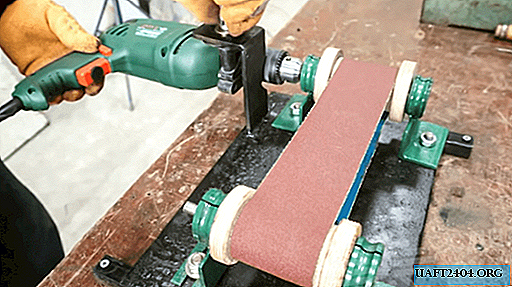

For finishing (finishing) machining of parts and workpieces made of wood or metal at home, usually use a belt grinder. It is much more convenient and safer than a grinder with a petal circle.

You can make the simplest belt grinding machine yourself from bearings for bearings. Due to its compact size, the machine can be used both in the workshop and in the garage. A network electric drill is used as a drive.

First of all, we cut round details from plywood using a crown on a tree. Then you need to drill one hole in each circle (in the center). We put the blanks on the hairpin, and then glue them together. We install bearings on the sides.

The main stages of work

From a metal corner (building), cut four pieces of the same size. We drill in two holes in one of the shelves, and then with the help of a grinder we make a slot. Next, remove the outer race from the bearings (cut in half) and weld to the corners.

As the basis for a homemade belt grinding machine, you can use a sheet of metal 3-4 mm thick. Mark and drill holes for fixing the corners. After that, install the plywood rollers. If there is a lathe, you can make solid ones from wood.

At the last stage of work, we weld the legs to the base, and then we assemble the parts. In the video on our website you can see the detailed process of manufacturing a belt grinding machine from bearings for bearings.