When sawing chipboard and hardwood, the cutting teeth of the band saw blade become blunt very quickly, so they have to be sharpened periodically. You can do this in different ways - for example, on a sharpening machine or using a dremel. The first option is quite suitable for these purposes, but using a dremel to grind the teeth is not very convenient.

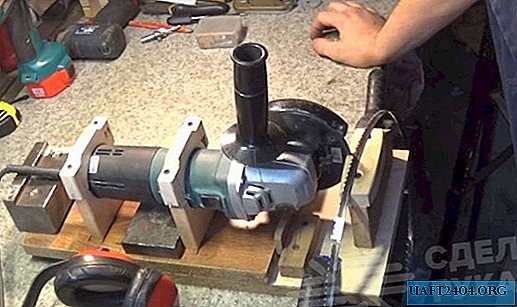

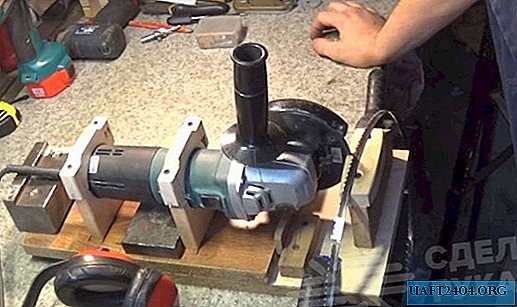

In this review, we will consider one of the options for sharpening tape blades using a grinder - it is advisable to use angle grinders with speed control. However, you can use a conventional angle grinder.

Even at maximum speeds (11-12 thousand rpm), a conventional cutting disc does not burn the cutting teeth of the blade. The quality of sharpening the canvas in many respects does not depend on the speed of rotation of the disk, but on the feed and the degree of pressure. If there is no speed control on the angle grinder, a smaller circle can be installed.

Features of sharpening a band saw

It should be noted right away that using a simple grinder for sharpening teeth without a speed control is not so dangerous compared to a dremel, which works at 30,000 rpm.

As practice shows, sharpening a tape blade using angle grinders is much more convenient, faster and more comfortable than using the same dremel.

And this is explained very simply - the circle of the dremel is perpendicular to the axis, and the diameter of the circle cannot be larger than the diameter of the body. Therefore, sharpening the teeth at an angle of 90 degrees is very problematic, because in this case, the sharpening angle will have to be along the rear face, which will lead to the fact that the height of the teeth will be different.

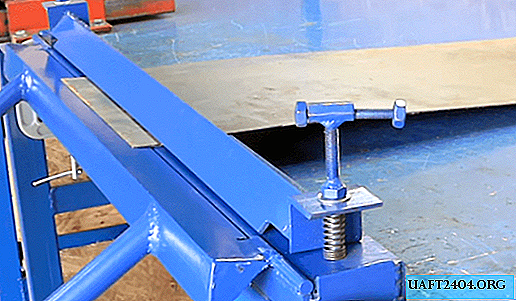

Using an angle grinder, you can easily grind the "front corner" of the teeth without touching the "rear", so their height remains the same and the blade cuts the workpiece with all the cutting teeth. To install the grinder on a workbench, a homemade device is used, which is a stand, two mounts and a work table for supporting the tape web.