Share

Pin

Tweet

Send

Share

Send

Will need

We will try to get along with simple materials that cost almost nothing:

- empty spray can;

- two aluminum tubes of different diameters and lengths;

- jet bolt and two ordinary bolts;

- cotton wick;

- metal cap from a glass bottle.

The diameters of the tubes, bolts and holes must be coordinated with each other.

In order to make a burner, we will need the following tools and devices:

- metal sponge for washing dishes;

- homemade cutting device;

- screwdriver;

- drill chuck and 2 drills of different diameters;

- vise;

- grease;

- scissors.

The procedure for manufacturing an alcohol burner

We take an empty aerosol can and with a metal sponge for washing dishes we remove the color from its lower part.

We clamp the interchangeable blade of the construction knife between the wooden block and the bar with two screws passing through the bar and screwed into the bar. Only the tip of the blade should look out.

We place another block of the right height under our cutting device in order to cut off a cup of the required size from the aerosol can. We install the cutting tool on a hard, even surface, put a spray can nearby and begin to rotate it, resting on the tip of the blade. As a result, we get a circular incision along which we separate the lower part from the upper.

In a cup closer to its bottom we drill a hole manually with a drill, which is not difficult, since the thickness of the metal is tenths of a millimeter.

From the inside, insert a bolt with a central hole - a nozzle.

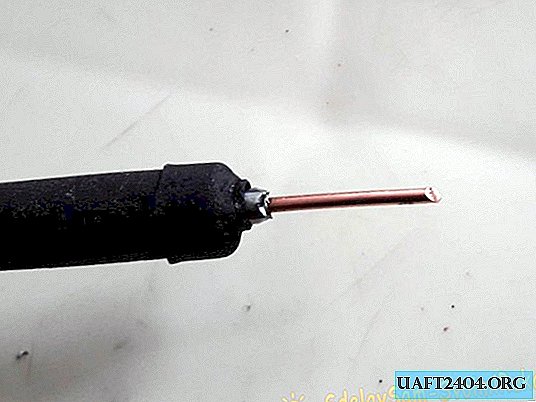

Clamp the long bolt in a vice so that the rod is directed vertically upwards. Apply grease to the threads. We use a bolt to thread several turns of thread in a soft aluminum tube on both sides.

On the side in the tube closer to the end we drill a hole equal in diameter to the nozzle hole.

We put it in a tube and pass a strip of cotton cloth rolled into a bundle along the entire length.

We pull the cotton in the tube and cut off both ends at the level of the ends with scissors.

We twist the tube with the fabric onto the shaft of the nozzle bolt.

In a short aluminum tube of a larger diameter closer to one end, we drill through holes, spaced in height, and with longitudinal axes at 90 degrees.

We insert a tube with side drilling into the lower holes of a short thick tube so that the small hole is directed upwards. At the end of a thin tube, we screw a short cap screw.

Our alcohol burner is basically ready for use.

Burner check in action

To prepare the burner for stable operation, we heat a short tube. To do this, fill the lid of the glass bottle with alcohol and put the tube into it. We also pour fuel into the glass and set fire to the alcohol in the lid.

As the burner heats up, fuel begins to flow through the nozzle from the cup, then it impregnates the cotton tow and reaches the hole at the end of the thin tube.

Gradually, combustion stabilizes, and a steady flame occurs above the upper end of the tube. If you place a test tube with water in it, then after a short time it will boil.

When the need for the burner disappears, the flame is blown out, and the remainder of the alcohol from the cup is poured into a storage container.

Share

Pin

Tweet

Send

Share

Send