In this review, the author shows how to make a home-made machine for sharpening hacksaws on a tree with your own hands.

A feature of this design is, first of all, in its compactness and versatility. On a home-made grinding machine, you can sharpen hacksaws with both a large tooth and a small one.

First of all, from the profile pipe 30x30 mm, four workpieces must be cut (at an angle of 45 degrees on both sides).

We recommend reading: how to make a powerful cutting machine from a Bulgarian do it yourself.

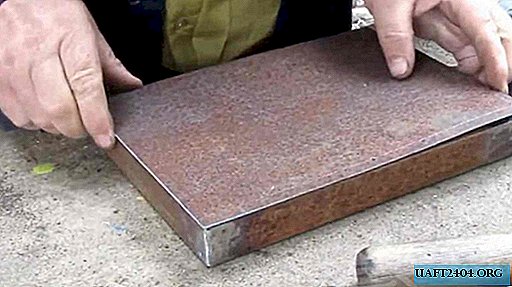

From these blanks, the author welds a rectangular frame. Before welding, the edges of the profile pipes must be cleaned with a grinder.

Welds will also need to be cleaned with a cleanup or flap wheel.

The main stages of work

In the next step, the author cuts a rectangular piece of sheet metal. It will need to be screwed to the frame from the profile pipe.

It is necessary to make markings and drill mounting holes in the frame (base) and the sheet of metal, and cut the threads into them.

The author uses countersunk screws as fasteners. To do this, you will additionally need to make poty.

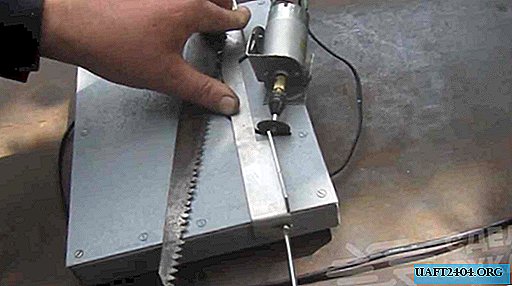

Further, the author makes a mount for the electric motor. Moreover, it is desirable that he be more powerful. In this case, an electric motor from an old MFP is used.

Homemade mounting allows you to change the position of the motor in three planes, which is very convenient when sharpening hacksaw blades.

We install the mount on the movable part, which is attached to the base, and make a slot in the base in the form of an arc.

From an aluminum corner, the author makes a device for fixing the saw when sharpening. For this purpose, an angle of 25 * 25 mm is used.

In the end, it remains only to disassemble the entire structure, clean it with a grinder, paint and reassemble.

The author fastens rubber legs to the bottom of the base. Thanks to this, the machine will stand stably on the surface of the table.

Details on how to make a homemade machine for sharpening hacksaws, see the video.