In this review, the author shows how it is very simple to make a convenient desktop for a barber out of available materials (who does not know, this is a male hairdresser).

To make such a table, a profile pipe and plywood are required. Additional elements in the form of a mirror with backlight can be added already, as they say, in place.

The first step is to cut off eight blanks from the profile pipe. Of these, the master welds two sides of the frame of the working table.

The main stages of work

At the next stage, the two sidewalls are connected to each other using four jumpers (also from the profile), which the master placed in the upper part and in the middle of the frame.

In addition, another rectangular contour from a profile pipe is welded in the upper part of the frame.

After that, the tabletop and the lower shelf are cut out of plywood. On the countertop from the bottom, the author makes a frame: cuts 4 pieces of plywood of the desired width and glues them.

Then it will be necessary to cut a few more blanks from plywood and sheathe them “windows” on the sides of the frame directly under the countertop.

The final touch - and you're done

A drawer is also made from plywood. The master decided to make the bottom out of a fiberboard sheet. A partition is installed inside the box itself, which divides it into two departments.

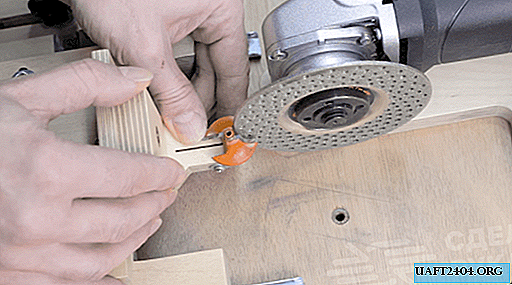

It is advisable to round off the edge of the countertop using a milling cutter. So the desktop will look more aesthetically pleasing.

Next, you need to disassemble everything again. Parts from plywood must be treated with a grinder, and the metal frame must be primed and then painted.

The tabletop and other details can be varnished on wood or mineral oil. After that, you can start assembling the table. The drawer is mounted on furniture rails.

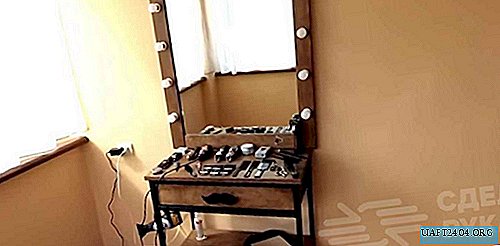

The finished desktop for the barber, made of profile and plywood, looks like this. Additionally, you can install a mirror (or you can mount it just on the wall). This is at your discretion.

For details on how to make such a simple and convenient table with your own hands, see the video on our website. Like and post comments.