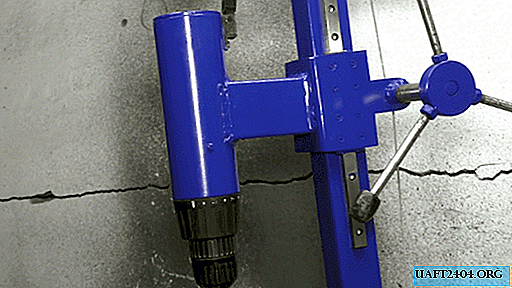

This homemade tool with carbide tips has a very simple design and will be indispensable in the processing of metal workpieces. In particular, it is used for marking the surface of sheet steel and other metal products.

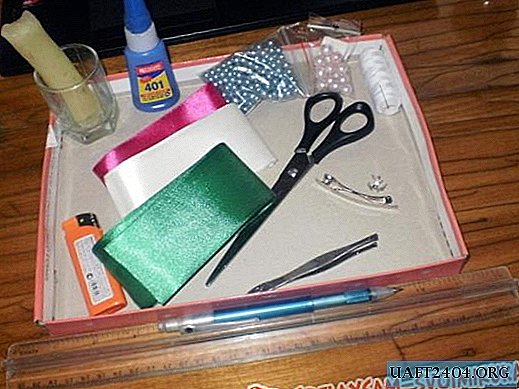

A round cross-sectional wire with a diameter of 6.5 mm will be used as the main material for the manufacture of the marking compass. The swivel joint can be made of a 4 mm thick steel plate. Solderings for a compass can be made of a carbide rod with a diameter of 2.5 mm.

The process of making a marking compass

From the wire we cut two pieces of the same length (about 12-13 cm). We find the center of the workpieces and drill a hole in them. Then we make a small longitudinal cut on the end. In the resulting hole, insert pieces of a carbide rod.

When the handles of the marking compass are ready, we grind them well with a grinder. Then we cut out two round parts from the steel plate, which will be used as a hinge for the compass.

To do this, first markup on the surface of the plate, and then with the help of a grinder we cut out round hinges. We weld them to the rods, and then drill a hole in the center for bolting. Holding the compass handles in a vice (closer to the base), bend them at a slight angle.

After grinding and painting, the home-made compass for marking is completely ready for use. See the video on our website for a detailed tool manufacturing process.