Share

Pin

Tweet

Send

Share

Send

Will need

In addition to the old hacksaw for wood with worn teeth, we will need for our purpose:

- device for cutting teeth (stapler);

- hammer;

- grinder or emery wheel;

- trihedral file;

- clamp for holding the saw during sharpening;

- small dense cardboard.

Stapler design

You can do it yourself in a home workshop. The main nodes cutting the teeth is a matrix with a through slot of a triangular shape, in plan resembling the shape of a saw tooth. The punch entering the matrix can rotate around its axis.

In order to carve teeth of different heights, there is an adjustable emphasis that can be shifted to one or the other side, which leads to a change in the depth, and hence the height of the tooth. This is possible due to elongated holes and bolts that secure the stop to the base of the stapler.

The die and punch should fit into each other with a minimum but guaranteed clearance. The working (cutting) edges of these two parts must be 90 degrees.

How to use a stapler

Our tool is extremely simple. Nevertheless, in order to test the stapler’s performance, gain skills and confidence in working with it, a little training will not hurt.

Cutting teeth on a cardboard blank

To do this, install the stapler on a solid and massive surface, lift the punch and under it on the matrix, until it contacts the stop, we install a cardboard sheet. Then we lower the punch to the surface of the cardboard and apply one sharp blow to the butt of the punch. The result is a cutout.

We shift the cardboard to the right or left by one step and repeat the operation. We take out the material from under the working bodies of the stapler and see the tooth profile surrounded by two notches. Continuing the cutting procedure, we can get the required number of teeth. This is where our training ends.

Felling teeth on an old saw blade

We start by removing old teeth. This can be done using a grinder or an emery wheel. The result should be a straight line, which will serve as the basis for cutting new teeth.

As last time, we set the stapler on a massive base: a piece of rail, an anvil, a metal pancake, etc. In advance, of course, we set the depth and angle of cutting, which is determined by the type of saw and its size.

Attention! If we cut teeth only on one side of the blade, then its metal, which has elasticity, will lead in one direction, and by the end of the work it will take an arched shape. To prevent this from happening, it is necessary to cut 3-4 teeth on one side of the blade, turn it over and cut the same number of teeth on the other side.

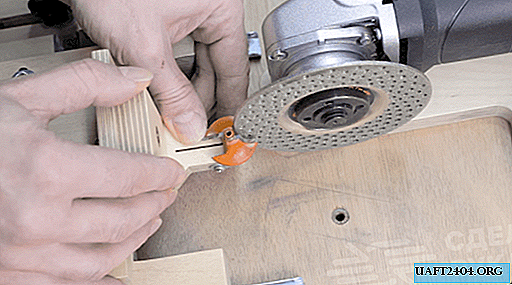

We install a metal sheet between the die and the punch as far as the stop in the limiter, and holding it with one hand, with the hammer we apply one sharp blow to the butt of the punch with the hammer.

We shift the blade by one tooth and repeat the operation again. Moreover, do not worry that the base of the hollows between the teeth is rounded: in the process of sharpening, they will take the necessary shape.

Sharpening new teeth of an old saw

For this, we traditionally use a trihedral file, but in order not to damage adjacent teeth, we grind one of its faces on an emery. Also, such an innovation allows the formation of the necessary geometry of the bottom (base) of the cavity between the teeth.

For sharpening the saw, it is convenient to use a wooden clamp, which consists of two wedges - wide and narrow. Wide has the ability to pivot on two pins. A saw blade is laid under its front part, and a narrow wedge is driven in from the side of the trailing edge, thanks to which a wide wedge presses the blade to the base of our device.

The tooth must be sharpened not from the bottom up, so that the metal does not wrap around the edge of the tooth, but rather from top to bottom, then the metal is simply cut off and the edge of the tooth becomes sharp.

Share

Pin

Tweet

Send

Share

Send