Cheap kitchen knives do not differ in high quality workmanship, and most often they have an “Achilles heel” with a plastic handle. If the handle of the knife is broken, then you can make it a worthy replacement - a beautiful cork handle.

To do this, you need a small sheet of balsa wood, which can be bought at the market or in a hardware store. Also, to give a cheap Chinese knife a more stylish look, the master decided to make him an original bolster from a piece of brass.

The first step is to bring the blade itself in order - to grind and polish the surface. Then, a piece of a semicircular shape is cut from a brass billet, a slot is made in the center of which.

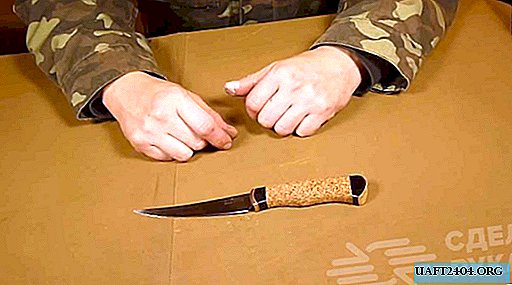

The process of making handles for an old knife

Since the master got a knife with a broken-off “shank”, first you need to cut a new short “tail” with the help of a grinder. Then he will need to weld a piece of a bolt or a long stud with a thread on the end.

Then you need to mark the cork tree sheet into small rectangles, and then cut them with scissors. From these pieces a knob handle for a knife will be made.

In each “fragment” of the cork tree, a hole needs to be drilled in the center, and then the pieces are mounted on a stud welded to the “shank” of the blade. Each "layer" must be smeared with glue.

At the last stage of work, it remains only to handle the handle, giving it the desired shape. For details on how to make the simplest cork handle for a knife, see the video on the site.